M.E. Manufacturing Engineering – Admission Brochure

Virtual open day for M.E. Manufacturing Engineering – View

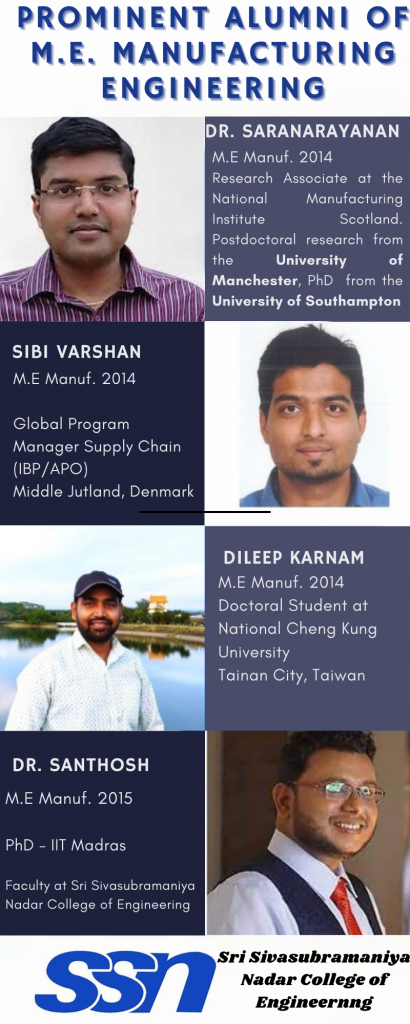

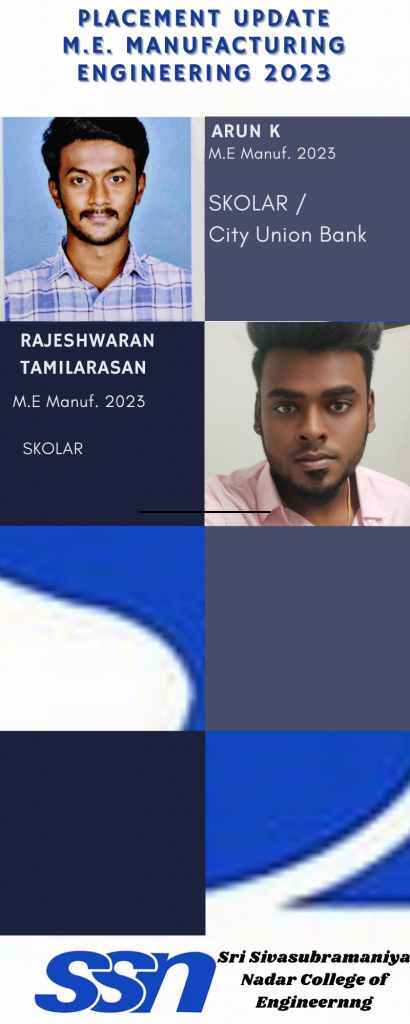

M.E. in Manufacturing Engineering is an advanced level course that aims to bridge the knowledge gap between the manufacturing industry and the academia through need of the hour courses such as Additive Manufacturing and Robot design and Programming with hands on experience on state-of-the-art 3D printers and Robots, while also catering to the growing demands in MEMS, Nanotechnology and Composites. The Program seeks to establish a balance between Industry readiness and Research progress by encouraging the students to indulge in academic research in cutting edge areas of Welding, Composite material processing and Numerical modelling through handheld pedagogy, whose outcomes can be envisaged from their impactful journal publications and their passion to pursue a PhD.

The curriculum comprises of the following CORE MANUFACTURING SUBJECTS:

- Micro Manufacturing

- Robotics and Automation

- Advances in Casting and Welding

- Mechanical Behaviour of Materials

- Materials Testing and Characterization Techniques

- Computational Methods and Optimization Techniques in Manufacturing

- Additive Manufacturing

The following LABORATORY COURSESare also compulsory:

- Industrial Modeling and Simulation Laboratory

- Casting and Welding Laboratory

- Robotics and Automation Laboratory

- Additive Manufacturing Laboratory

The following are some of the electives that are offered:

PE – I : MATERIALS RELATED

- Composite Materials and Applications

- Advanced Engineering Materials

- Smart Materials and Structures

- Industrial Surface Engineering

- Micro Electromechanical Systems

- Ceramic Science and Technology

PE – II : ADVANCES IN MANUFACTURING

- Virtual Manufacturing

- Artificial Intelligence in Manufacturing

- Nanoscience and Nanotechnology

- Lean and Cellular Manufacturing

- Sustainable and Green Manufacturing Practices

- Advanced Metal Forming Process

PE – III : DESIGN RELATED

- Computer Aided Product Design and Lifecycle Management

- Design for Manufacture, Assembly and Environment

- Finite Element Methods for Manufacturing Engineering

- Advances in Metrology and Automated Inspection

- Design of Jigs, Fixtures and Press Tools

- Tribology in Design

PE – IV : MACHINE TOOLS RELATED

- Advanced Tool Engineering

- Metal Cutting Theory and Practice

- Machine Tool Control

- Fluid Power Automation

- Numerical Controls in Machine Tools

- Prognostics and Condition Monitoring of Machine Tools

PE – V : INDUSTRIAL MANAGEMENT RELATED

- Quality and Reliability Engineering

- Business Operations Integration

- Data Analytics

- Supply Chain and Logistics Management

- Manufacturing Management

- Maintenance Engineering

Students have the option to choose these OPEN ELECTIVES:

- Business analytics

- Industrial safety

- Operations Research

- Cost Management of Engineering Projects

- Composite Materials

- Waste to Energy

- Introduction to Data Science

Project Work

- Project work is carried out in 2 phases, semester IV being dedicated exclusively for the second phase of the project.

To know more about the department, Click here